GSG Plug Gages - Manufactured in Steel, Stainless and Carbide

Reversible Plug Gages

•The Reversible plug gage

has the advantage that it can be reversed and used at the opposite end when one end becomes worn and goes out of tolerance.

•The gaging members are simple pins that can be removed from the handle by loosening the collet nuts at the ends.

•Each end of the handle is color coded, green for Go and red for No-Go.

Depth steps are available upon request.

•Available in Steel, Carbide and Chrome.

•Extra long members available.

•Gaging surfaces are hardened to Rc 58-62.

The reversible plug gage was more recently introduced and standardized, after it became possible to reach the necessary precision with centerless grinding and lapping techniques. It has the advantage that it can be reversed and used at the opposite end when one end becomes worn and goes out of tolerance.

The gaging members are simple pins that can be removed from the handle by loosening the collet nuts at the ends. Larger gage members can be identified by marking the size and tolerance on the ends. When the gage is too small to permit this, it is not possible to distinguish between the Go and NoGo members without resorting to measuring instruments. The collet nuts at the ends of the handle are different colors – green for Go and red for NoGo. This traffic light system is often used in attribute gaging.

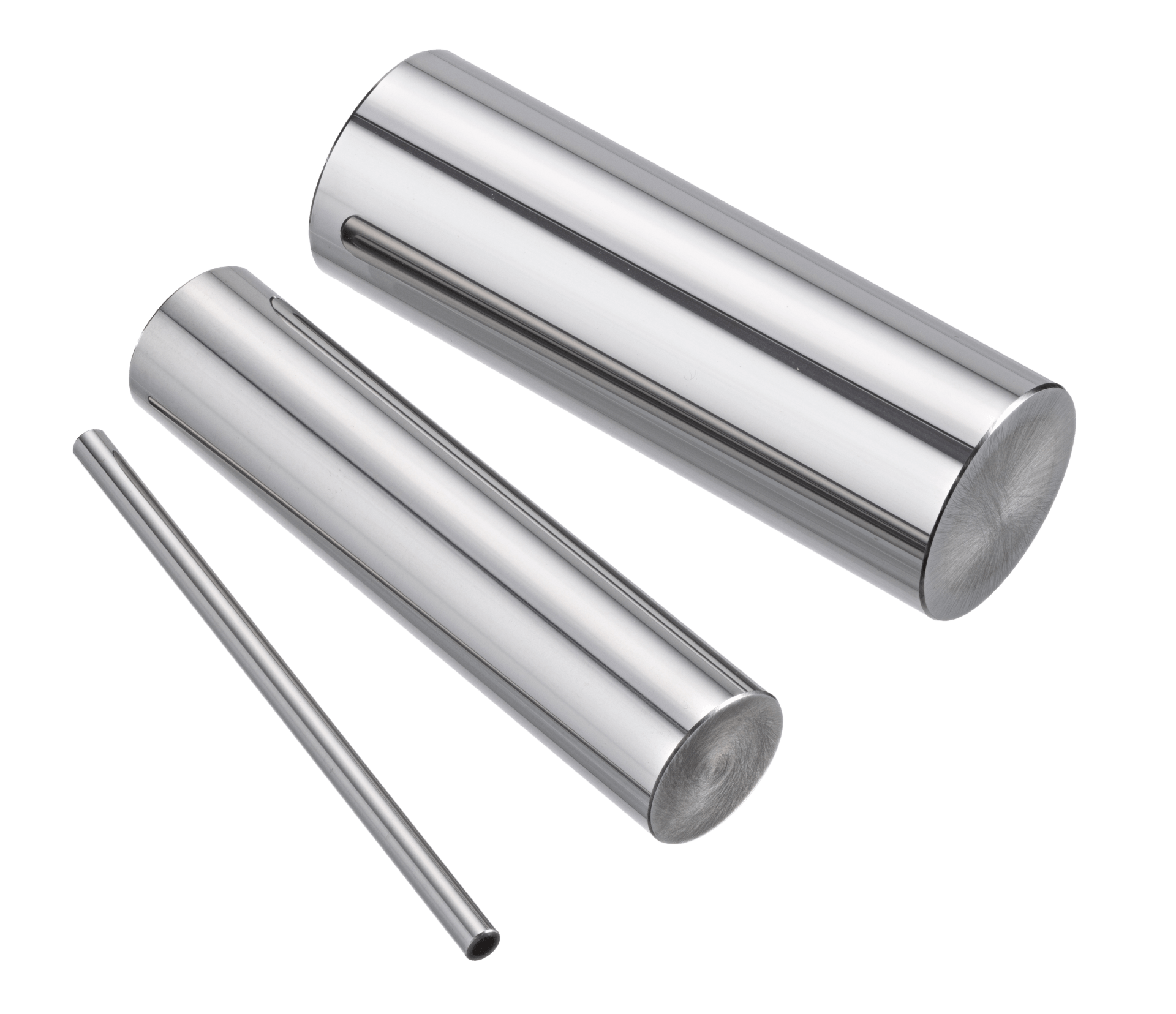

Taperlock Plug Gages

•The Taperlock gage is named because of the tapered shank, which locks into the tapered hole in the end of the handle.

•Used for gages up to 1 ½ inches.

•As a further aid in identification, the Go and No-Go members have a different length of gaging surface. It is permissible to make the No-Go gage shorter because it is not supposed to enter the part.

•Depth stops are available upon request.

•Available in Steel, Carbide and Chrome.

•Gaging surfaces are hardened to Rc 58-62.

The taperlock gage is so-called because of the tapered shank, which locks into the tapered hole in the end of the handle. It is the time honored standard of the American Gage Design Committee, for gages up to 1 ½ inches in diameter.

There is an advantage in the fact that these gages have the size and tolerance marked on the shank of the members. If or when they are removed from the handles there is no confusion as to what they are. As a further aid in identification, the Go and NoGo members have a different length of gaging surface. It is permissible to make the NoGo gage shorter because it is not supposed to

enter the part.

Trilock Plug Gages

•The Trilock design has been found best suited for gages between 1½ and 8 inches in diameter.

•The Trilock feature is the source for the name of this design. The handle has three prongs on the ends, which fit into three grooves equally spaced around the central hole of the gage members.

•A bolt holds the member to the handle and the Trilock grooves and prongs stabilize the member.

•Like the pin (reversible) type, Trilocks are reversible, since either face can be locked to the handle.

•Available in Steel, Carbide and Chrome.

•Gaging surfaces are hardened to Rc 58-62.

The taperlock and pin (reversible) type designs are not well suited for large, heavy gages. The trilock design has been found best suited for gages between 1 ½ and 8 inches in diameter. The trilock feature is the source for the name of this design. The handle has three prongs on the ends, which fit into three grooves equally spaced around the central hole of the gage members. A bolt holds the member to the handle and the trilock grooves and prongs stabilize the member.

Like the pin (reversible) type, trilocks are reversible, since either face can be locked to the handle. Thus, if the reversibility feature, allowing double the use, is important to the user, he or she can order reversible gages for all size ranges.

Military standards, which military contractors are generally required to follow, call for pin type reversible gages from the smallest sizes up to .510 inches and for taperlocks from .510 to 1.510 inches. Trilocks are recommended for the sizes from 1.510 to 8.010 inches.

Progressive Plug Gages

•In some special cases, a little gaging time can be saved by putting the Go and No-Go diameters on a single gage member.

•A progressive plug, for example, is suitable for checking a short hole, which is open at both ends.

•Obviously, the hole cannot be deeper than the Go section of the plug.

In some special cases, a little gaging time can be saved by putting the Go and NoGo diameters on a single gage member. A progressive plug, for example, is suitable for checking a short hole, which is open at both ends. Obviously, the hole cannot be deeper than the Go section of the plug.

Progressive style gages are usually in the taperlock style, but any of the designs can be made progressive.

For general questions about plug gages, please use the forms below: