Southern Gage's Employees Stay for Decades... Just What Do They Do?

By: Liz Buttermore

Members of the Southern Gage crew outside the facility a few years ago.

The Glastonbury Southern Gage company has been in Houston County for decades. Employee Ron Smith recently called the Herald and spoke about the type of work the company does, and he also mentioned two longtime employees at the company, Jimmie Smith and Kenneth 'Duck' Deason. According to General Manager, Gerald Rye, Deason has been with the company 58 years, Jimmy Smith 53 Years, and Engineer, Mike Rose, 52 Years. Rye, himself a Houston County native and the only General Manager in the company's history from Houston County, has been with them 45 years. Current and former employees Ron Smith, Larry Patterson, Brant Lamastus and Rye, all gave us a little background and history about the company and just what they make there.

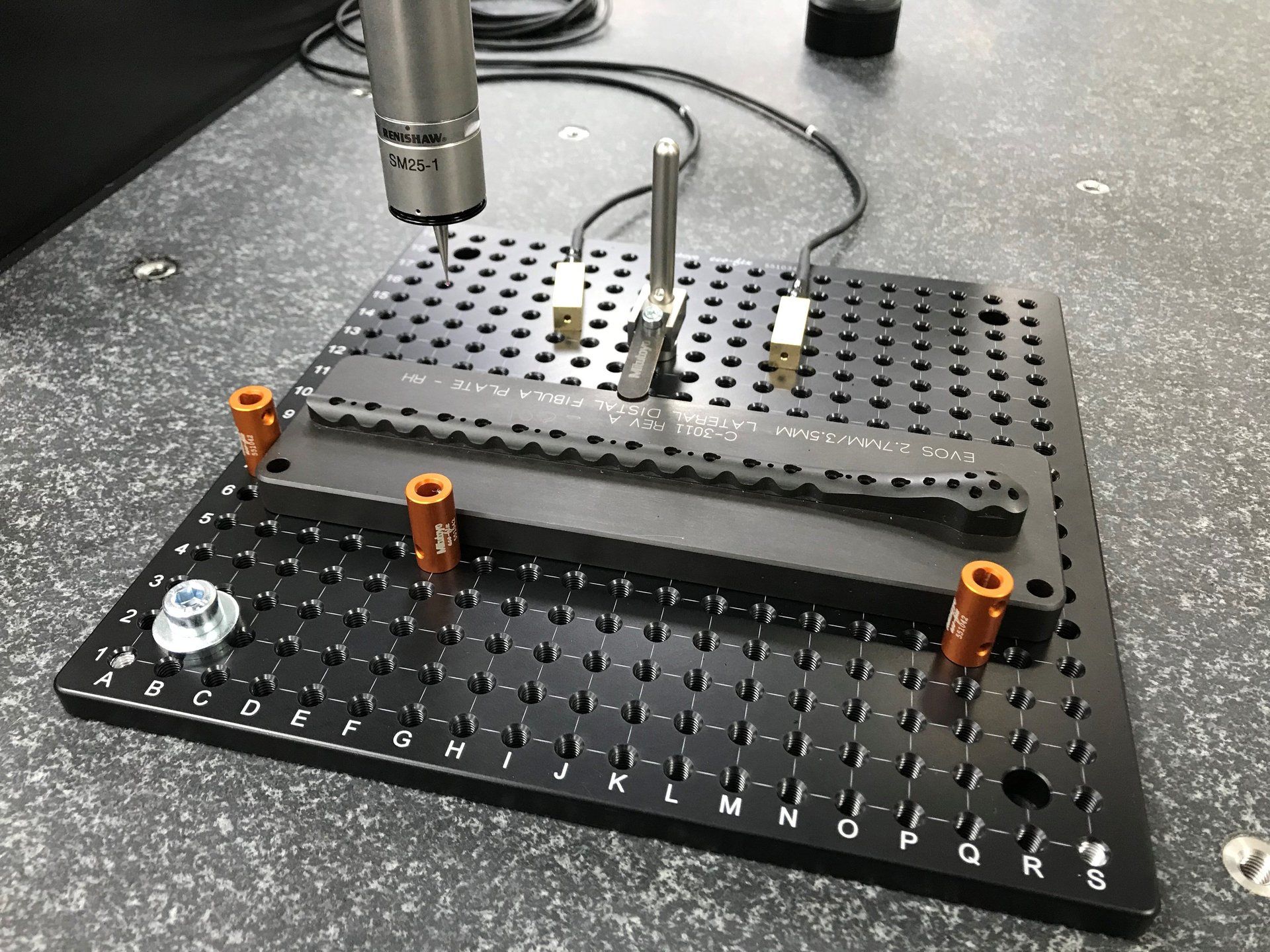

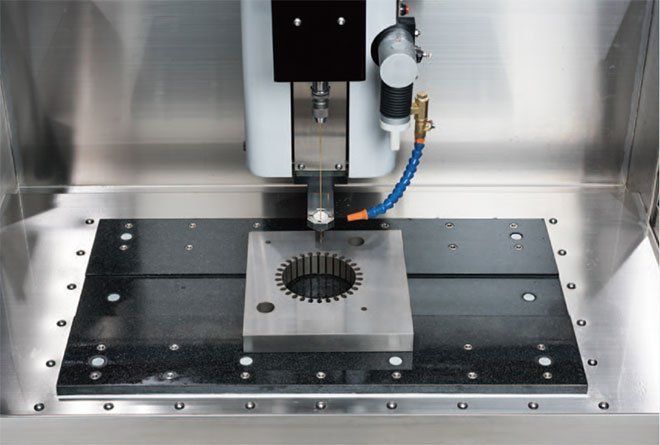

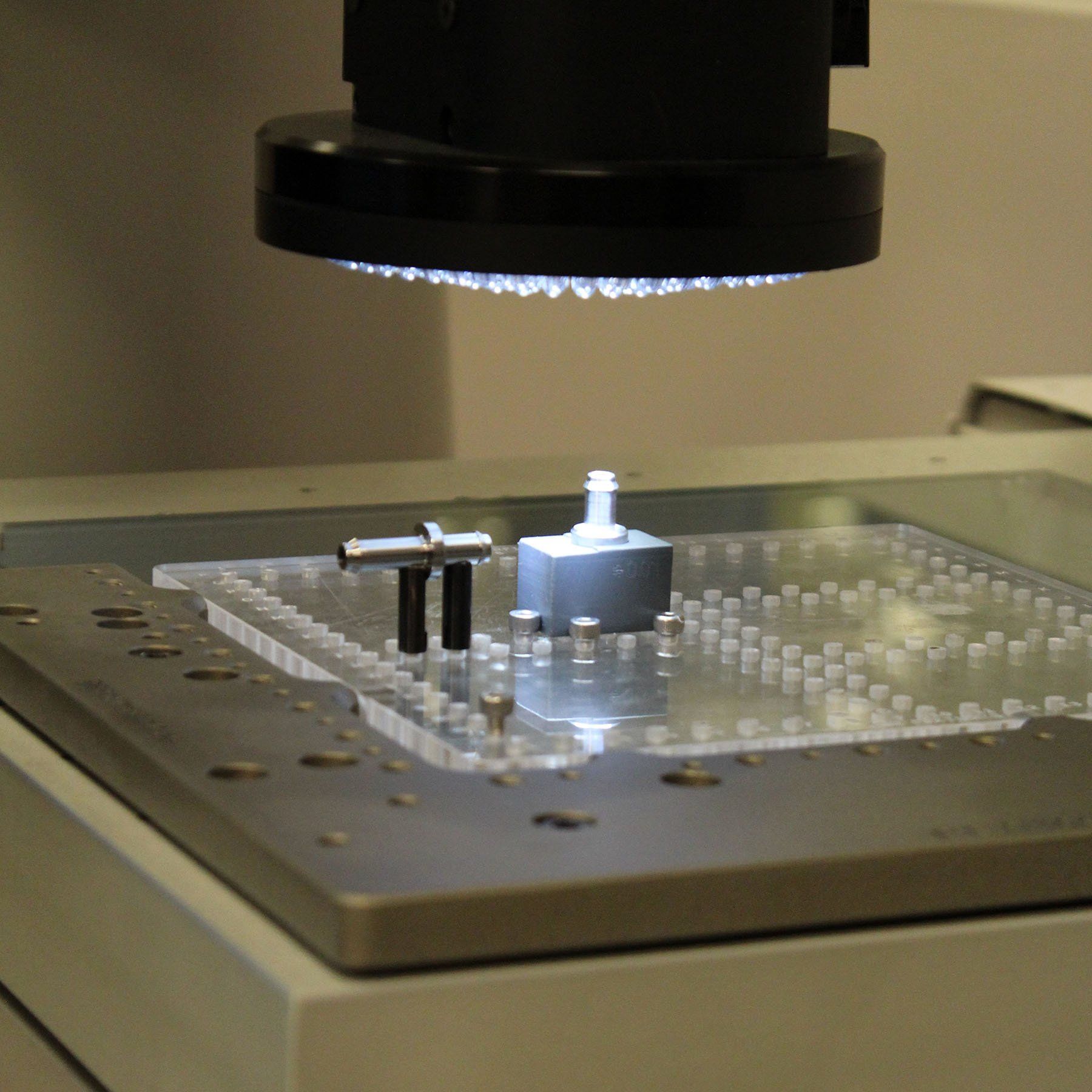

"There's so many people who don't know what goes on in this building," said Ron Smith. He explained employees make gages used as inspection tools for parts on, "everything from eyeglasses to I-Phones", physical screws and objects used in surgery on the human body, parts on oil rigs, master gages for gun makers and gages for measuring intricate parts for auto makers Honda and Ford.

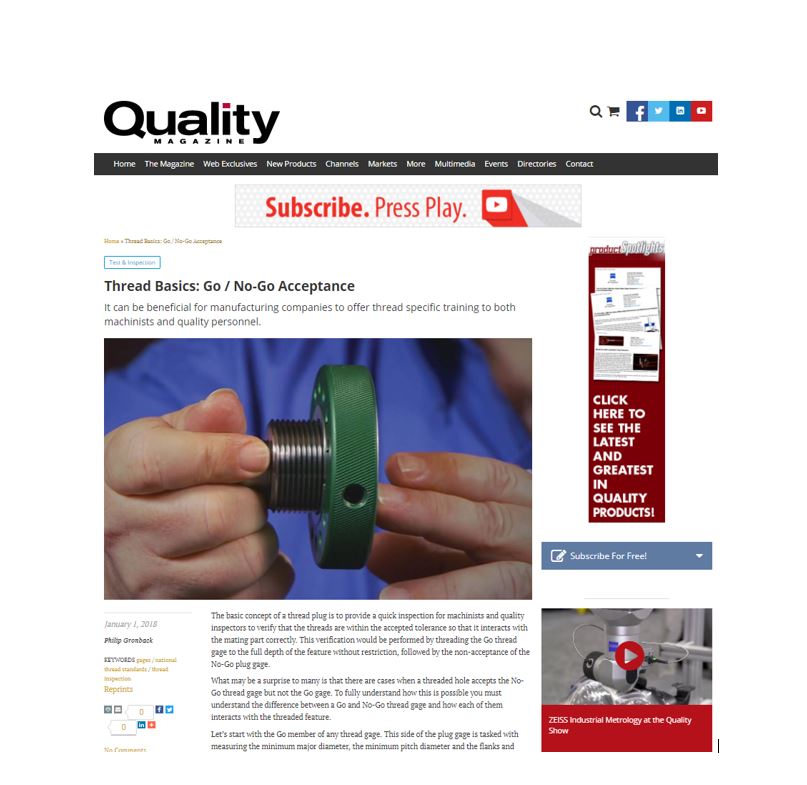

Retired employee Larry Patterson explained, "When a company has to drill a hole and put threads in it and it has to be precise, then they need something to see how precise they are. We made the gages that would screw into that hole. We made one that would fit and then one that would not fit, because it was a little too large. If the first one went in and the other didn't, they knew they were in balance." Patterson said the gages were called "gos" and "no gos". Considering human hair is between 2 and 6 thousandths of an inch, Patterson said Southern Gage's specifications were to a tenth of one thousandth of an inch. Rye confirmed this. Some companies that have used the gages include: General Dynamics, Moog, AVCO, and many airplane manufacturers, and the petroleum industry. Rye added, "It's a very unique business. We deal with automotive and medical, aerospace, defense, and all aspects of the business."

Brant Lamastus was a 43 1/2 year employee of the company, working in the sales/customer service department. "I enjoyed every minute of it. I got to the point where I was ready to retire," said Lamastus. He told us he looked at blue prints, and sent quotes to companies on gage prices. "They made a lot of gages for the oil industry, where they drill down to get oil," said Lamastus. He explained companies purchase the original gage, but don't have the capabilities of reproducing them. Gages can run anywhere from $150 to several thousands of dollars, depending on specifications. Lamastus, who sits on the Stewart-Houston Industrial Park/Development (SHIP) Boards said of Plant Manager, Gerald Rye, "When we try to get people in here who want to look at the spec building, he's been very open with the Industrial Board to show them Southern Gage, walk them through, and show them the workforce. He's been excellent to work with." Lamastus said a lot of the training is on the job and there is a probationary period. "You don't have a lot of turnover down there," said Lamastus. This is proven by the number of years several employees have stayed with the company. Rye spoke about the specialized machine work done at the plant. "The work we do here, you can't get in a trade school. They can teach you some basics, but the training actually has to be done in-house here." He added, "Southern Gage has been a staple here in Houston County since 1956. It's kind of like a large family here. We have second and third generations. People come here to stay. It's a very unique business and we're very proud to be here in Houston County, and have our workforce. People come here to stay."

Over the years, Southern Gage has been housed in three different locations in the County. According to Archivist, Melissa Barker, the three locations were: Midway Drive, Mobley Lane and its current location, at the Stewart-Houston Industrial Park. The Mobley Lane location is the old Zero Systems building. Rye said this was a secondary facility for the main on one. At the intersection of Midway Dr. and Rocky Hollow, was where the main facility was located (now Perdue Acoustics). Rye said besides the SHIP site, the only other one (parent company- Alpha Q) has a similar Glastonbury Gage company in Connecticut. Although operating under different names/other companies, (Glastonbury) Southern Gage has been in operation in Houston County since 1956.

Rye gave a simple, but powerful example of the importance of gages. He spoke about the Great Chicago Fire. (According to history.com, in 1871 the Great Chicago Fire killed 300 people, left 100,000 homeless, burned for two days, and caused an estimated $200 million in damages.) Rye said the fire hoses which were needed to battle the blazes in 1871, did not hook up to one another. "Hoses years ago were made in different places. When they got them, they wouldn't interchange, they wouldn't hook up. So, the gauging industry, we still make a fire hose spec that ensures that if a 2 inch fire hose connector is made here, or overseas, or wherever it's made, they will screw together."

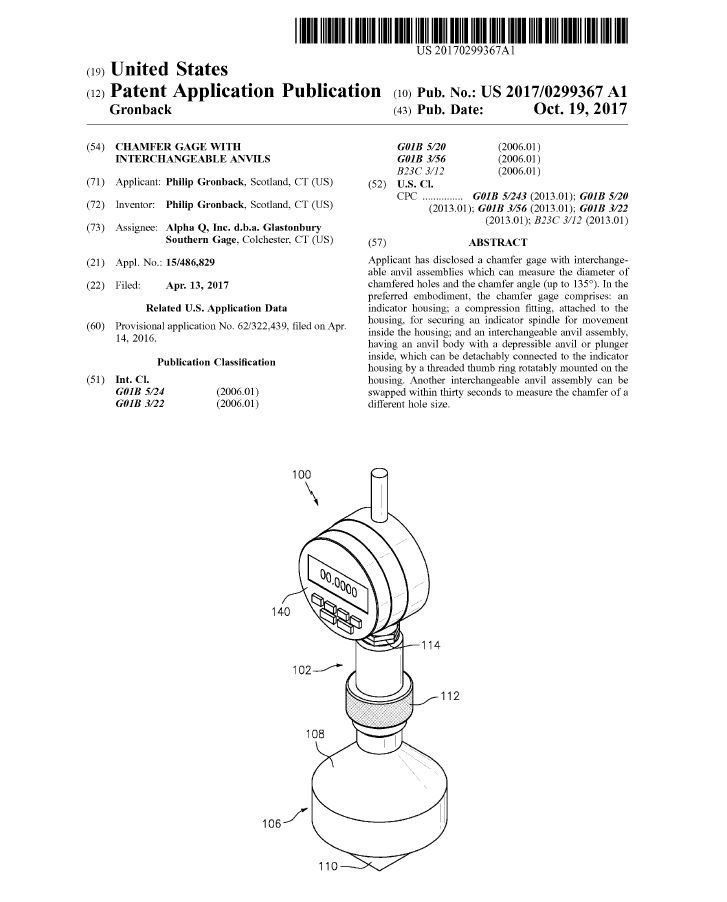

We did a story in the Herald last year regarding gages made right here at the Industrial Park that were used to measure specifications used in ventilators during the COVID crisis. Rye spoke again about the medical industry's usage of gages. "There's a lot of medical applications these gages are used to check. They are not actually used in the body, they're actually used to check the parts going in the body- bone screws, catheters, etc.," Rye explained. "There's literally hundreds of different gages we do. If you look at gages, there's so many different sizes. We stock thousands of different gages. The rest of our stuff is all custom built. In fact, we have an engineer here, Mike Rose who is among the top three in the country. If the medical industry needs to make something and control it as they make it, in the US, most of them will come to Mike Rose and he will engineer the gages they need, and we'll manufacture those gages to check whatever they want to check. It could be anything from a hypodermic needle to dial up/gauge the exact amount of insulin. There's a gage to set that, so when you dial it up you know you're going to get that much insulin. Mike engineers those. He's probably the top 2 or 3 in the country if not the number 1, as far as engineers," Rye said. He added various gages for the military are made at the factory, including those to measure time fuses for bombs, the hatch of a tank, bores of gun barrels, military scopes for Leupold & Stevens and more. "There's a few other gage companies in the country. We probably make the most specialized gages out of all those, because we have the engineering ability here to do that. The other companies don't have the engineering ability we have. It kind of sets us apart from the rest of the gaging industry. We're very proud of this business here, and very proud of the people here," said Rye.