GSG - QuikChek's

QuikChek CMM Artifact: Principles of Operation and Application

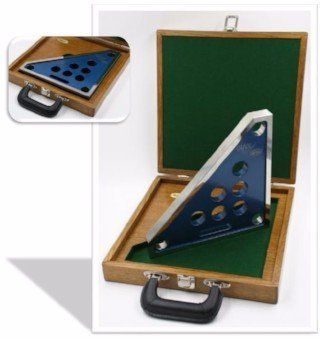

The QuikChek Coordinate Measuring Machine (CMM) Artifact is a precision-engineered tool designed for the interim verification of CMM performance. This artifact facilitates the assessment of a CMM's linear, angular, and squareness accuracies, ensuring reliable and consistent measurement data between formal calibration cycles.

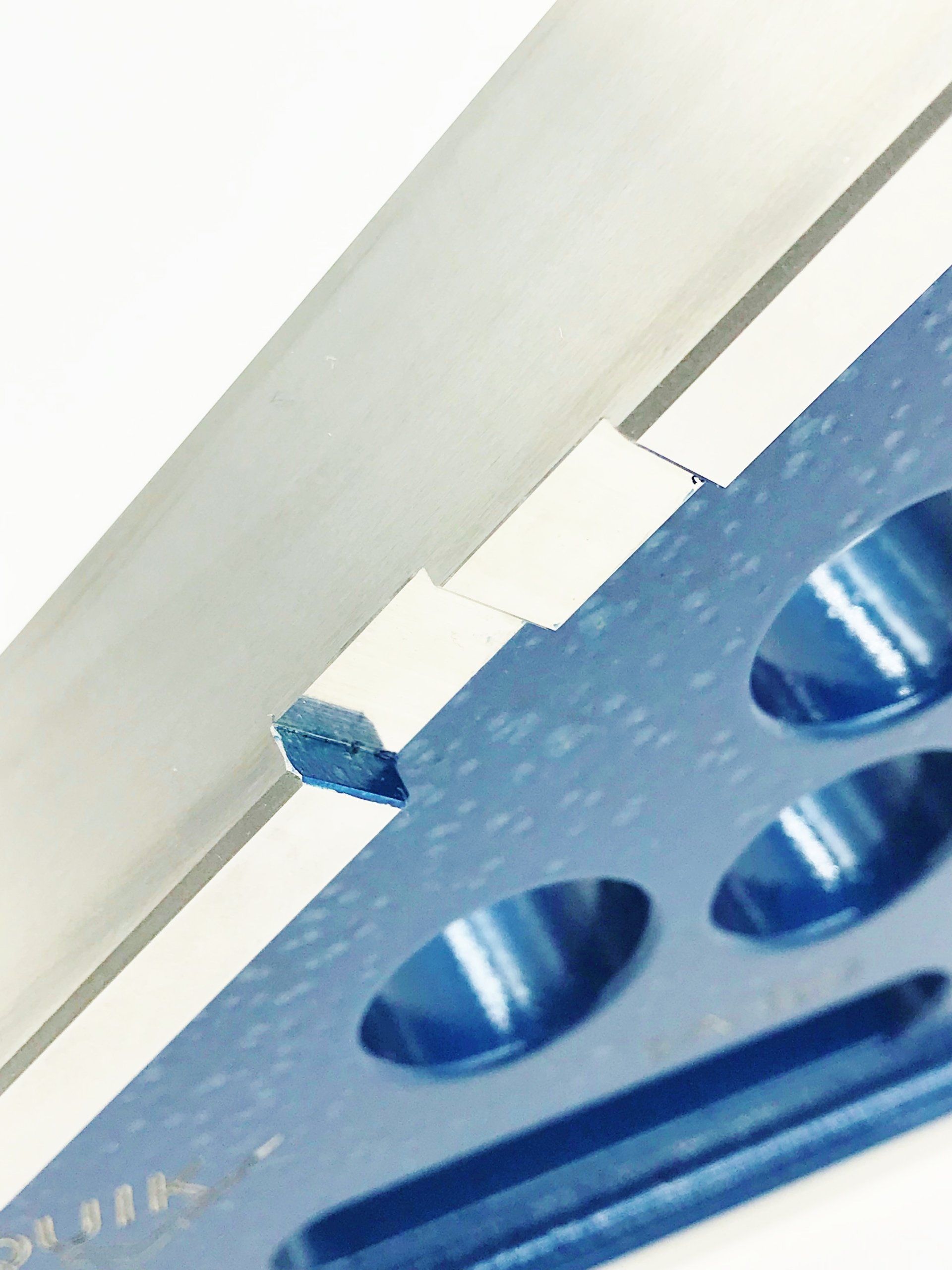

The core functionality of the QuikChek artifact lies in its three certified bores. These holes are manufactured to exacting tolerances and their diameters and center-to-center distances are certified and traceable to national metrology standards. By measuring the location and diameter of these bores along the X, Y, and Z axes, a comprehensive evaluation of the CMM's volumetric accuracy can be performed. The precise geometry of the certified bores enables the verification of:

- Linear Accuracy: The known, certified distances between the bore centers are used to verify the accuracy of the CMM's linear scales in the X, Y, and Z directions.

- Squareness: The perpendicularity of the machine's axes (X to Y, X to Z, and Y to Z) is verified by evaluating the measured positions of the three bores, which form a known right-angled triangle in three-dimensional space.

- Angular Accuracy: The arrangement of the bores allows for the verification of the CMM's ability to measure angles accurately within its measurement volume.

It is critical to note that only the three specified bores are the calibrated and functional features of the QuikChek artifact. The external surfaces of the artifact body serve no metrological purpose and are not intended for measurement or verification activities. Their sole function is to provide a stable and robust platform for the certified bores. The artifact is constructed from hardened and thermally stabilized materials to ensure dimensional stability and minimize the influence of environmental fluctuations on the verification process.

By incorporating the QuikChek artifact into a regular quality assurance regimen, users can proactively monitor the performance of their CMMs, detect any deviations from expected performance, and maintain a high level of confidence in their dimensional measurement results. This interim verification is a crucial component of a comprehensive quality management system and serves as a valuable supplement to annual professional calibration.

New Item! 5.00" QuikChek

Our new 5.00" model comes equip with depth steps precision ground with in .0001 for verification of your depth accuracy