Protecting Intellectual Property

Patent Process 101 - In Plain English

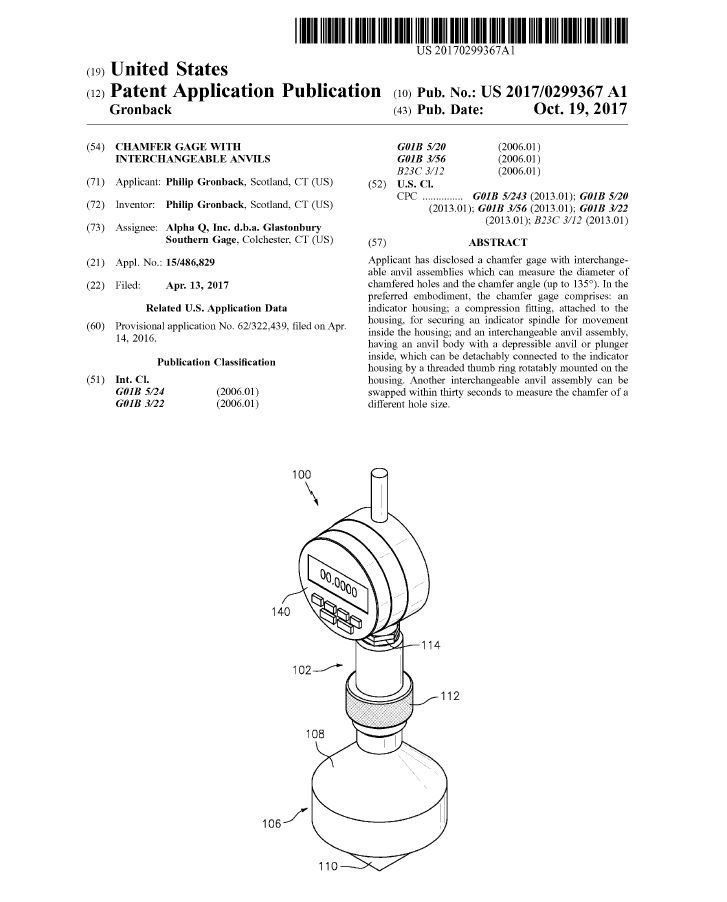

Protecting intellectual property is an important step for any company to take. That being said, it is also a long and expensive process. After acquiring a good patent attorney the first step will be to file for a "patent pending" status. This protects your rights for a period of one year while applying for a full patent. During this time your attorney will be performing a patent search to ensure your idea is not encroaching on any existing patents. In addition to this, the "Abstract" which is basically the description of your idea and it's inner workings will be scrutinized, re-worded and placed into the proper language for the full patent submission. This language needs to be very specific and highlight the uniqueness of your idea. The better that description is, the more protected you will be and the better the chance your application will be accepted. Speaking of acceptance, it is very common for the US Patent Office to respond back to you with several additional requirements after your initial submission. Take careful note of the "respond by" dates and do so in accordance with them or you'll be starting all over from scratch.

My suggestions for patenting your idea or product would be to follow these guidelines; (1) Decide if this is truly an idea that you can benefit from financially and one that makes sense to patent? (That can be by selling the rights, actually producing and reselling it yourself or even selling partial rights to part of it) Obtaining a full patent is an expensive venture and in most cases in excess of 20k. The best thing you can do is to use the 1 year waiting period to prove out your idea/invention and test the waters of profitability. The initial patent application will cost you around $2500. This will gain you the "Patent Pending" status which offers you protection. If you decide during that time that you don't think your invention will produce as much fruit as you initially thought, you don't need to submit the final application which will save you tens of thousands. At that point your patent pending will just silently go to the patent graveyard; (2) Find an exceptional lawyer... and I'm not talking about guy that closed your mortgage for you. Do your research and ask around. An experienced patent lawyer can make the difference between acceptance and denial, long process or short. (3) Lastly, celebrate! If you receive that confirmation after the long and exhausting process of obtaining a US Patent, you deserve it. And after you bath in the satisfaction of this accomplishment, get to work on the next one! Innovation is fueled by new ideas and there's always a way to make a better mousetrap.